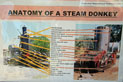

ASMA Steam Donkey Exhibit at the Kennedy Gold Mine

The ASMA Steam Donkey Exhibit at the Kennedy Gold Mine, features a restored 1945 Clyde Iron Works

steam boiler connected to a steam engine and wire cable winch. The steam donkey was fully restored to

peak operating condition by the Amador Sawmill & Mining Association [ASMA] in 2008 and has been

featured at the Amador County Fair, the Arnold Logging Jamboree, and other regional shows.

Although known as #2, it was the

first of two donkey engines to be restored, and the first to steam-power the Amador County Fair Sawmill

and Mine exhibit in 2008. It now makes its home at the Kennedy Gold Mine as a fully-operational historic

steam powered donkey engine: living history for the enjoyment of visitors to the Mine museum.

The Kennedy Mine used a older but similar steam donkey engine, to build the first wood headframe over

their newly developed east shaft in 1900. That headframe served to sink the shaft and bring the mine

to over 4,000 feet in depth. It was also used in the construction of the 100 stamp mill. After a disastrous

above ground fire erupted on September 7, 1928, burning down most of the surface plant and the wooden headframe,

the steam donkey engine was used again in late 1928-1929 to build the now famous steel headframe you see today.

The new taller, robust headframe served the mine well until all gold mines were shut down in 1942 because of

WWII. When the mine shut down, the depth was then over 5,912 verticle feet, the deepest

gold mine in North America

at that time.

Steam donkeys were used in the contruction industry, logging industry, in maritime applications,

anywhere portable power was needed. Other types of steam boilers were larger, horizontal and heavy,

whereas the steam donkey was relatively light and nimble. It could be sent up in a small area in

tight spaces, and could move itself around on wood or iron skids to re-position for the next job. The early ones burned stove

wood, but it was easily adapted to burn other fuels like oil, such as the 1945 Clyde Iron Works model we

feature. The logging industry used steam donkeys extensively, and logging was

an important part of the mining

industry. Mine timbers were a necessary part of safety to shore up

tunnels, adits and shafts for mine workers.

A Logging Donkey

Logging Steam Donkeys were stove-wood powered steam boilers with

engines used in the woods by

loggers, to haul logs by cable to a certain spot to "yard" or stack

them for removal to a mill. They were also used to run "high leads",

cables attached to tall poles and pulley systems to pull logs out of

the woods. Also known as a "Yarding Donkey", they also

loaded wagons, narrow-guage logging trains, and sometimes were even mounted

on the train itself. Using the Kennedy Mine as an example, Logs from the local forests were brought down

directly to the Kennedy first by oxen, mule or horse teams pulling great wagons, and then

by trucks, such as ASMA's Fageol Truck.

The logs were stacked in great piles next to the Kennedy saw mill,

likely by using another steam donkey, and sawn into large timbers

for the mine. They also cut boards and planks to build the above

surface plant, the large Mine Office seen today on the hill, the

mill, the iconic tailing wheels, bunkhouses for the miners, and more. Some of

the best examples of the sawmill lumber are visible inside and outside of the Bunk House

Managers Residence [private residence today].

The Logging Donkey Steam Engine & Cable Winch

The Steam Donkey was usually built on wooden or metal skid plates that could be slid from area to area in the woods by the donkey operator using cables attached from the cable winch to trees, and also by using oxen, mule or horse teams. The steam boiler was wood-fired, and the resulting steam powered a small single piston steam engine attached to a cable winch or two.

Logging Donkey Crew

The Logging Donkey Crew would consist of the boiler tenders, wood cutters, cable setters, and even stock wranglers to take care of the team of either oxen, mules or horses. In a day, when much work was done by hand, there were no lack of jobs for people!

History of the ASMA Steam Donkey #1 and #2

Coming soon...